Advice on the purchase of used Guzzi models from 350 - 750cc

Advice on the purchase of used Guzzi models from 350 - 750cc

Translated with www.DeepL.com/Translator

preface

In many trade journals used purchase consultations are shown, often also supported by me and/or other dealers. Of course, these reports also cover the market overview, the individual models and the history. Since the reports are usually limited to a maximum number of pages and therefore the editors have to compress the reports, which means that some information falls by the wayside.

That's why I decided to write my own second-hand purchase advice for the little guzzis, which certainly doesn't cover everything and therefore is meant to be a supplement.

This reflects my personal opinions and experiences of more than 20 years of working with this topic (since 1985 I have personally been driving the small models and since 1994 founding Guzzi e piu in Bruchsal, since 2007 in Hambrücken).

general

They are considered to be discredited, vulnerable and unreliable ("always break anyway") This is all wrong (if they have been put in order correctly). My own machines have already covered more than 100.000km (1. Lario 123.000km, 2. Lario 130.000km, V65TT 138.000km). Annual holidays of about 3.000km are proof that you can rely on the technology. And the developers at Moto Guzzi were no different than other manufacturers and tested their product before it was shipped. Only what does a tester do? He sees that he gets the kilometers together and accelerates and there the little guzzis keep perfect.

It is true, however, that due to often long downtimes or "barn finds", the vehicles often show typical stand damages which, if not repaired, often costly ends.

A further problem is that by the simple technical construction everyone dares to screw on it and by ignorance many actually bad parts are installed again or errors are not recognized. These are the machines on which "everything was done" and they still don't run properly. The danger of buying a "tinkered object" is extremely high here.

Damage to the valve control unit and actuator is also caused by incorrect handling or use, such as underspeed operation and incorrect oil/oil quantities.

Advantages of small guzzis are:

- Low weight.

- Low seat height (especially V35 and V50).

- Super handling (especially V35 and V50 drive almost like a bicycle).

- Super brakes (integral system takes getting used to, but ideal for people with small hands as there is more power in the foot).

- The low centre of gravity makes it very suitable for beginners and small persons.

- Maintenance-friendly construction.

- Low maintenance and servicing costs (set of tyres incl. new hoses and assembly approx. 200 Euro).

- When it falls over, it doesn't break much (crash-friendly).

What they want for smooth operation:

- Thorough inspection and correction of all defects.

- Correct equipment.

- Regular oil changes, especially during short-distance operation.

- Correct operation (2-valves above 3,000 rpm and 4-valves above 4,000 rpm) is good for valve control, transmission and drive shaft.

What they don't want:

- Low-speed operation à High load on the valve control system and shocks on gear wheels and the cross-joint joint increase wear on these components.

- Mineral engine oil à

- Thin engine/transmission oil à low damping factor and high wear on gear wheels, drive gears and camshaft.

- Long oil change intervals in the gearbox and final drive à corrosion on bearings + gears.

- Non-lubricated length compensation of the cardan shaft à Damage to the universal joint and shift forks.

Often the question arises as to what a small guzzi can cost, or why our (Guzzi e piu) small guzzis are so "expensive", whether this machine is recommendable,...........

- Our machines are inspected by default for these damages and partly repaired in case of safety-relevant defects. This results in the higher basic price but we think that our machines often end up cheaper than a machine for 1,000 or 1,500 Euro with many damages and especially the uncertainty of what still has to be done. Our machines are basically sold with a condition report, so that all involved parties are satisfied at the end. Afterwards I have an overview with these typical stand damages, which are also checked in our Guzzi e piu vehicle check (duration approx. 2 hours).

- Therefore, it is better to avoid vehicles with extremely low mileage.

- Vehicles with high mileage are the better choice in many ways.

- They have been moved regularly and have only wear and tear that can usually be repaired cheaply.

- Many wear repairs have already been made.

- Experience has shown that machines that often look particularly good, often show this kind of damage due to a lack of movement.

- How much does a small guzzi cost? Experience has also shown that for a small guzzi (irrespective of engine capacity) 3.500, -- Euro have to be taken into account for the machine and the technical preparation.

- If you use this setting to call on a small guzzi and are willing to spend this amount, you can only be happy and you are not angry that the budget will be exceeded unplanned.

- If this is too much, it's better to keep your hands off the machines.

- If you needed less at the end, you had a bargain. In this 3.500 Euro are only technical works like e. g. new battery, steel flex brake lines, new tires,..... Contained. But not the painting or "beautifying" of the machines. This is extra.

Common sources of errors of small guzzis

Hello friends of the little Guzzis V35 - V75 (all models).

At this point I would like to show you some places where damage often occurs.

Often, the poor little guzzis can't do anything about it, but this is due to mishandling, lack of information or inadequate care.

Also, there are often hints about this which are pushed into the wind or postponed until a really big damage is there.

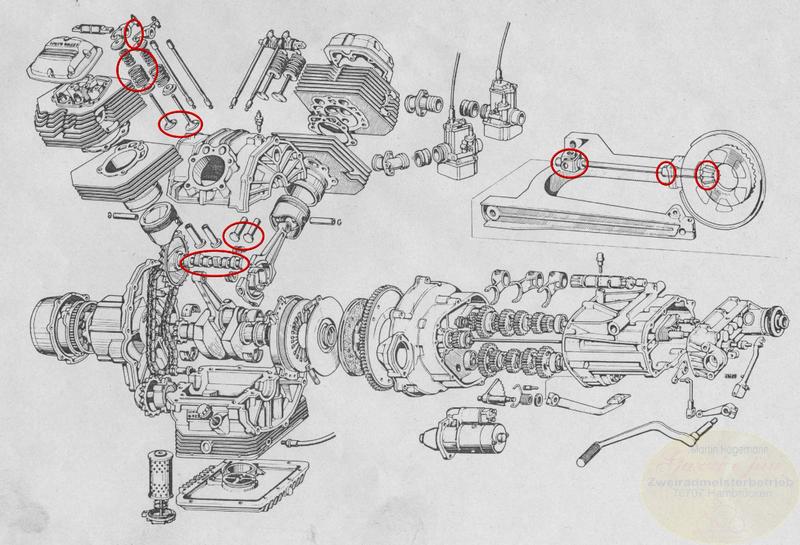

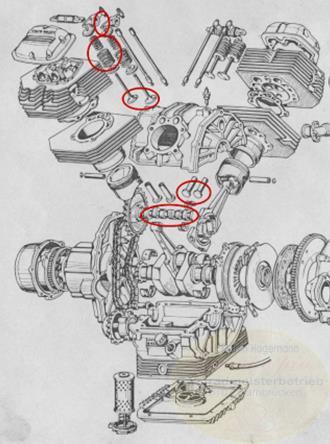

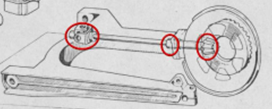

On the picture I have marked some areas which I will mention in the following.

Table of contents:

Table of contents:

- motor/valve control

- gearbox

- cardan shaft and final drive

- electrics

- brake system

- running gear

- General sources of error/operating errors

- filling quantities/viscosities/adjustment data

-

Engine/valve control

- Wearing part Rubber sleeve between the rocker arms (2-valves) this hardens with increasing age and grows larger, so that there is no sufficient oil supply for the rocker arms and an increased amount of oil mist in the valve cover, which cannot be removed via the oil separator (machine sometimes lubricates from the air filter box). In addition, a lack of lubrication is created on the rocker arm shafts, which means that the rocker arm shafts can run in and cause additional noise.

- Valve adjusting screws are often stretched or even torn as a result of too tightly tightened lock nuts (you can see on a stiff lock nut or valve adjusting screw) which can then break off and possibly cause engine damage.

- Problem with valve springs (double springs). They are too strong for all older models (for underspeed driving) and were later (with introduction of the 750 engines) changed to simple progressive springs for the 2-valves. It is recommended that all 2-valve models be retrofitted to the new valve springs, which may only be fitted with the corresponding valve spring plates and valve wedges. For the 4-valve models there is no solution from Moto Guzzi but I can do a conversion.

- Problem with valve breakage. The valves stretch due to the too hard valve springs until they break, no problem with high speed driven engines and engines with the new valve springs.

- Problem valve in the combustion chamber. Some of the valve wedges wear out, causing the valve to fall into the combustion chamber. No more problems after conversion to the new valve springs.

- Camshaft problem.

- Run-in camshafts are the rule for the 4-valves but also for the 2-valves with high mileage and for mainly underspeed driven vehicles because the load on the camshaft is particularly high here. This problem can be eliminated with the 2-valves by retrofitting to the new valve springs and with the 4-valves by various conversion measures.

- Important for durability is the use of tough oil (15W50 or 20W50) as it has a high damping factor.

- In any case, a fully synthetic oil must be used, as the motors are subject to quite high thermal loads.

- Idle speed min 1200 rpm.

- No underspeed driving.

- Cylinder Coating: Removal of cylinder coatings on the first V35 and V50 models that were delivered with hard chrome plating. NIGUSIL-coated cylinders are rarely affected by this.

-

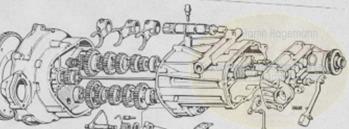

Gearbox

- Changed oil fill quantity (see fill quantities at the end of this report) is best with mineral oil, as some bearings do not tolerate synthetic oil.

- Due to the mostly too low oil filling quantity, damage often occurs to the front gel bearings and the 5th gear wheels.

- Shifting forks are often run in by pressure on the transmission output shaft from the cardan shaft due to stiff length compensation.

- Slight pitting on the gearwheels in places, but this can usually be reused without any problems.

- In the case of rare oil changes and frequent short-distance operation, increased condensation water content in the oil, which can lead to rust/corrosion of gearwheels and bearings during service life. In extreme cases, even rusted components. Therefore IMPORTANT! ANNUAL CHANGE!!!!

-

cardan shaft and final Drive

-

Cardan shaft

- Toothing at the back and length compensation are often dirty or the grease is heavily resinified so that it is stiff.

- In case of stiffness in the slider, every up and down movement causes a pressure on the universal joint, which is destroyed over time and damages the shift forks in the transmission. For this reason, it is essential to remove the final drive every one to two years (the best time to do so is when changing the wheel outdoors anyway), clean and re-grease the gear teeth of the cardan shaft, the slider and the final drive (I personally use a heat-resistant dry lubricant, as this does not resinify or bind dirt or Teflon grease).

- Every 2-4 years also remove the swing arm and check the universal joint for easy movement of the cross-joint and check that the cross-joint bushes are firmly seated!

- Cross-joint fracture is caused by wear of the bearings in the cross joint which is damaged by too much pressure (see above) or washed out of the lubricating film by steam jet on the rubber bellows. In the event of a breakage, the universal joint, swing arm and rear gear cover are usually destroyed.

-

final drive

- Axial play in the drive shaft due to destroyed tapered roller bearings of the drive shaft due to incorrect oil level in the final drive (see filling quantities at the end of this report).

- For correct oil level control, the swing arm must be horizontal before opening the inspection hole (see also workshop book extension) otherwise see previous point.

- In the case of rare oil changes and frequent short-distance operation, increased condensation water content in the oil, which can lead to rust/corrosion of gearwheels and bearings during service life. In extreme cases, even rusted components. Therefore IMPORTANT! ANNUAL CHANGE!!!!

-

electrics

-

ignition systems

- General: Leaking ignition coils due to often switched on ignition with the engine switched off. Here the whole current (approx. 5A) runs continuously over the ignition coil so that it can overheat. In the course of the years, the insulation dimensions emerge outwards (identified by a wax-like covering at the fixing points). In case of defective ignition coils, it is recommended to convert to a fully electronic ignition system as a complete set (such as Silent Hektik) immediately.

- Contactless BOSCH ignition system: due to old and heat damaged cables of the pickups, short circuits often occur. Easy to repair through shrink tubing and sealing compound. Often also used ignition rotors which have to be repaired by welding (important welding material must be magnetic). As with all electronic ignitions, voltage losses in the on-board electrics are also problematic. With voltages below 9.5-10.5 volts, little is happening with electronic ignitions.

- breaker contact ignition: worn contacts, defective capacitors (which only become noticeable when the engine is warm) and stiff centrifugal force adjusters often cause trouble with misfire and poor performance. Another problem is that today's capacitors and contacts are no longer suitable and wear out quickly (not only electrically but also mechanically).

- Motoplat contactless ignition system: defective ignition boxes, pickups and rotors. As with all electronic ignitions, voltage losses in the on-board electrics are also problematic. With voltages below 9.5-10.5 volts, little is happening with electronic ignitions.

-

on-board electrics

- Power losses

- oxidized connectors (especially the 15-pin connector with the thick red and brown wire) here, too much current runs over the connector. Remedy by relay switching. Which can also be purchased ready wired from us.

- Expanded contacts: through frequent disconnection and insertion or oxidation. Correction by bending or replacing.

- fuse box: widened contacts and incorporated fuses. Easy to fix with a set of new fuses and bend the contacts back so that the fuses are tight again.

- Vehicle mass: Due to soiling between the frame and the engine, it is often not possible to transfer the mass properly. Remedy by 2. ground cable from the battery to the starter attachment.

- Defective switches:

- Light switch: by converting from Bilux to H4 light, the switch is often overloaded and burns through. Simple remedy by using a relay circuit* so that only the control current runs over the switch. Then the switch becomes ancient. Relay circuits can be purchased ready wired.

- Power losses

-

brake system

- Soon more

-

running gear

- Soon more

-

General sources of error/operating errors

- Soon more

-

filling quantities/viscosity/adjustment data (red = original manufacturer's specification)

- Engine oil (fully synthetic): e. g. Motul 7100, Motul 300V or Agip I-Ride

- Old 2-valves with double valve springs: 2 liters 15W50 or 20W50

- All 2-valves with single progressive valve springs: 2 litre 10W60 or 15W50

- All 4-valves: 2 litre 20W50 or 15W50

- Gear oil e. g. Bel-Ray MC-4 or Agip Rotra MG/S

- 350 and 500: 1 litre 85W140 or 80W90

- 650 and 750: 1 litre 85W140

- V7 5-speed: 1 litre 85W90 or 85W140

- V7 6-speed/ V9: 0,5 litre 85W90 or 85W140

- Final drive: e. g. Bel-Ray MC-4 or Agip Rotra MG/S

- V35 - V7 III: 170ml 85W140

- V9: 210ml 85W140

- Fuel:

- V35 - V75: Super Plus 98 Octane

- From V7: Super Lead-free

- valve clearance

- o V35 - V7 II E0.15 / A0.20

- o Kl. 4-valve valve E0.10 / A0.13

- o From V7 III / V9 E0.10 / A0.15

The incorrect oil quantities usually result from incomplete documents of the users, because e. g. the gear oil quantity was later raised again to 1.0 liters and most users only have the general ledger in which the 0.9 liters are still indicated.

Have fun with the little guzzis!

Martin Hagemann -Guzzi e piu-

Last updated: 11 July 2017